IMPROVING CUSTOMIZED DESIGN WITH 3D PRINTING

Pengyu Ren

Purdue University

552 W Wood St

West Lafayette, Indiana, US

ren184@purdue.edu

Abstract

Design, especially industrial design, is connected firmly to the industrial and technology revolutions. After the first Industrial Revolution, the mode of production has been changed gradually from handicraft production to mass production with the use of steam power. However, with this method, the individuality and uniqueness of the products are reduced. All the products look the same, which can not satisfy the needs of consumers nowadays. This paper, based on the critical thinking about the mass production, analyses the limitations of existing production and design method, and suggests the customized design as a solution. Moreover, based on two case studies, try to explore how the 3D printing technology will help improve the customized design in the future.

Keywords-design; industrial revolution; mass production; 3D printing; customized design

1. Introduction

In ancient times, people had begun to make tools to help them hunting, fishing and grinding food. Stone implements are generally regarded as the earliest tools designed by ancient humans. In the modern era, after the first Industrial Revolution began in about 1860, mass production gradually replaced handicraft production with the use of steam power. There are many positive effects of it indeed, however, as every coin has two sides, we have lost something from that time. By going through the second and the third Industrial Revolutions, the production efficiency and speed have been significantly improved. However, on the other side, design, as an industry, has been gradually separated from the production process. One of the outcomes is that the creativity and ideas of the craftsmen, or designers, has been limited by many restrictions. With the standardization and serialization been used in the production process, products produced by machines all look the same. The individuality and uniqueness of the products are reduced, from this perspective, it is even a retrogress compared with the handicraft period. Even though mass production meted out large quantities of products in a small amount of time with lesser room for error as well as labor costs, it also resulted in products whose design was harder to change. As these products slowly lost their appeal, so did the value of the industry [1]. Although the manufacturing process has been updated throughout time, it seems like the capacity of the third Industrial Revolution has almost reached its limit.

2. Methodology

This paper firstly elaborates the limitations of the mass production and the outcomes of mass production. It conveys a fact that the mass production method can not satisfy the need of consumers nowadays. Then, by analyzing the need of consumers, it explains why customized design will be a trend of the future. And how to realize it by using the 3D printing technology. After that, by analyzing two cases of customized design using 3D printing technology, the paper elaborates the advantages of using 3D printing to improve the customized design. Finally, based on these two cases, a framework of how to do a customized design project with the help of 3D printing has been made.

3. Limitations of mass production

The mass production has lasted for about 150 years, even though it has been improved throughout times, it still has some disabilities, both in the aspect of production and design.

From the perspective of production:

(1) High cost

By the mass production method, the cost is not only the materials for production but also the cost for the production lines and tons of machines. Setting up the production lines is costly. When an error appears in the design or production process, it may lead to all the before efforts in vain. Moreover, minimum run quantities tend to be extremely high, so waste is another issue [2].

(2) Lack of flexibility

When there is one part wrong in the production process, it may affect the whole process, like the series circuit. So its error-tolerance is low. Moreover, this issue could result in a considerable loss of money and time.

In another situation, when a product is redesigned, the existing production line may need to be redesigned or rebuilt. One or multiple changes should be made to suit the new needs. Sometimes it has to change the whole lines. So its response speed for the market is low.

(3) Heavy labor demand

There are many production lines, like Foxconn, has a significant dependence on labor. Moreover, the work condition is not good, sometimes even worse. The repetitive works do not make any sense of achievement for its workers. So this leads to the low motivation of the workers. Moreover, because people are easier to make some mistakes in this repetitive and high-pressure works, it increases the defect rate.

(4) Supervision difficulty

Most of the mass production processes are large-scale, which means there are tons of devices and lines included in the process. So it is challenging for managers or regulators to supervise it. Even though there are digital systems can be used, they still need operators.

From the perspective of design:

(1) Low individuality and uniqueness of products

Because the mass production process is standardized and systematized, the outcome of it is the same. In this way, the products have no individuality or uniqueness. Only the color, size and other few choices are provided to the customers. Goods of uniform quality are turned out irrespective of the requirements of individual customers. Individual tastes are not, therefore, satisfied.[3]

(2) Obstruction in design

The limitation of the production technology and the production mold may lead to many difficulties in the design process. Sometimes design has to compromise with the limitations. It is indeed damaging to the creativity.

In a word, every Industrial Revolution has its limitations. When it can not satisfy the need of people, it is time a new revolution should come with brand new technologies, which may provide an entirely different way of solutions.

4. The need for customized design

It is not hard to find that it is the people’s need that drives the development of the design. In ancient times people use simple tools to solve the problem, it was the earliest type of design. However, in the view of modern people, we can not call a stone ax a designed product. From the need of problem-solving to the need for customization, people’s need changed during the time.

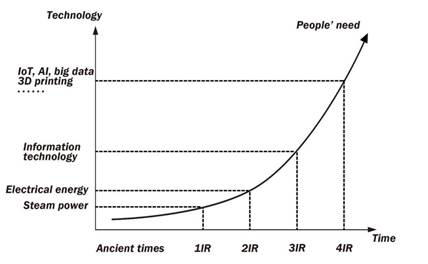

Fig 1. People’s need drives design and technology

The products produced by mass production all look the same. They can not satisfy all the consumers’ need nowadays. It was during the throes of the modern movement, when mass production had reached an all-time high, after which people started to come back to the roots. It was slow and steady, but gradually, the demand for customized design started to come back and eventually started an entire movement [1]. The customized design provides a good solution to this issue. In this method, design can be a service for everyone. Different consumers with different needs can get different outcomes. The only obstruction of realizing the customized design is the manufacturing process. Mass production can not make it because the outcome of production lines can not change. But with the development of 3D printing technology, the costs of time and money are reduced largely in recent years. Using 3D printing to realize customized design is feasible.

5. How 3D printing helps in the customized design process

3D printing, or additive manufacturing, is a technology that creates a physical object into a three-dimensional shape by printing layer upon layer from a digital 3D drawing or model [4]. From the production part, 3D printing production does not need lines of devices, and the 3D printers can print different things according to the changes in 3D models. It improved the flexibility of the production process. Moreover, with the automated method, it reduces the dependence on labor. From the perspective of design, it can fulfill more difficult tasks than the traditional one. Some complicated and hard been produced products are easily manufactured by the 3D printers. So this means there are fewer limitations for designers, in some way, increasing the freedom of design. In this method, it is the best choice to realize the customized design and makes the customized design more widespread.

Although there is a lot of customized design on the market, they are all simple designs and low-level customization, like printing a pattern onto a mug or T-shirt. But people have the need for product customization. The best news of all is that the manufacturing industry becomes increasingly customer oriented. The designs are driven by what the clients and consumers need [5]. So with the development of 3D printing, this need can be satisfied nowadays.

CASE 1

The earnotz, a personalized wireless 3D printed earphone, was a funding project on Kickstarter. This project originated from a critical thinking about the existing earphones. The earbuds all have the same size, but everyone’s ears are different. They can not fit all the people’s ears. And even the AirPods may give people a feeling that they may fall out of their ears, which may reduce many potential consumers. So to solve this problem, the earnotz project aims to use 3D printing as a method to give everyone a pair of suitable and comfortable earphones. The process of getting a pair is not very difficult. First, print a provided scale and position it on the ear to get the dimensions of the ear. Then use the mobile app to capture both of the ears by video or photos. Then they can 3D print the earphone by these data. An extra personalization service is provided, too. People can choose whether to add a picture on the shell or design their own shells by using 2D or 3D software. But this service needs the consumers themselves to make the 2D and 3D files.

The failure of this project may include many aspects. Although consumers can get the suitable size of the products, and this is indeed a good method to solve the pain point in earphone design, the appearance of the earphone is not very attractive. Though it was a customized product, a consumer was not able to join in the design part of the main body of the product. Moreover, consumers get the opportunity to design the shell of the earphone, but they need to do it themselves without the designer’s help. It is not a bad thing to have more choices. But when customers are given choices they can not handle them without the designer’s help. They won’t bother to choose them[6]. Actually, in the earnotz’s case, the customer only got the choice of size. The other choices were impracticable. By analyzing this project, a conclusion can be made: When it comes to the process of customized design, the designer must participate in every step of the design part, do the design with the client’s participation and preferences.

Fig2. Customer and designer’ s participation in earnotz’s design process

Even though this Kickstarter project did not make a success in the end, it provided a good case of using 3D printing technology to realize the customized design.

CASE 2

Another case comes from the custom jewelry design industry——the MARS fine jewelry. Different from the first case, in this situation the customer decided the direction of the design of the jewelry. The designer provides the design service to help make the idea come true. Both of the designer and the customer participate in the design process. And when the modeling process has been finished, a 3D printed wax model would be created. By using this wax model, it is easier for both the designer and the customer to communicate what changes would be made. Finally, using the lost-wax casting method, the molten metal is poured into a mold that has been created by means of a wax model. Once the mold is made, the wax model is melted and drained away [7].

Just regard the jewelry as a product. In this situation, different from the first one, it gives the customer more participation in the design process. And gives a good example of combining the 3D printing and a traditional way to produce and prototype the product. Moreover, the production process like the 3D printing process is always done by the 3D printing service providers, the jewelry customization companies do not need to own the 3D printing devices.

6. Prediction on customized design process using 3D printing

As mentioned above there are two cases of the existing customized design with 3D printing technology. Both of them provide some useful information:

Firstly, the 3D printing technology gives a total freedom of the design. Without limitations in the mass production, design works can be more creative. This is the base support of the realization of customized design. But this does not mean all of the parts of the product need to be 3D printed. Businesses often make the mistake of considering 3D printing for the simple replacement of an existing manufacturing technology [8]. The jewelry’s case elaborates that combining the appropriate methods of production is the most efficient way to manufacture.

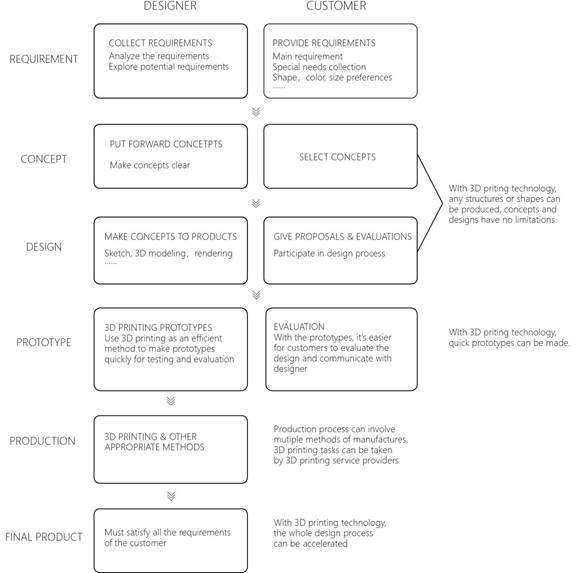

Secondly, as it is a customized design project, the customer’s preferences and proposals are very important. So both the designer and the customer should participate in the design process.

Finally, as it is predicted that “Research by consultancy firm A.T. Kearney finds that the global market for the 3D printing industry will grow to $17.2 billion by 2020” [9], there will be more and more 3D printers and 3D printing service providers in the fourth Industrial Revolution. The competition of these 3D printing companies will accelerate the development of 3D printing and make it a more extensively used technology. This means the production of products will be easier and cheaper. The customized design providers will not need to have their own 3D printing devices. This will help promote more customized design services appear.

So with these two cases’ help, a prediction of the customized design process in the fourth Industrial Revolution can be created.

Fig 3. Customized design process with 3D printing

7. Conclusion

In the environment of mass production, most products look the same. Consumers do not have many choices when selecting the products. But the standards of living and consumption of people keep rising. The demand for customization and personalization is increasing. With the fourth Industrial Revolution’s coming, the development of 3D printing technology will change this situation. 3D printing is not about replacing the mass production method, it is about making up the limitations of the existing manufacture methods. With the 3D printing technology, the customized design will be a new trend in the future market. The most important thing is that 3D printing makes it possible to produce different products for different customers, which gives a fundamental support for customized design. 3D printing technology not only gives the customized design more freedom but also makes it easier for the designer and customer to communicate with each other in the design process. It will help design become a service for everyone in the future.

References

[1] “Customized Design Vs. Mass Production-New Era For Designers, Artisans And Craftsmen”, http://www.daevasdesign.com/customized-design-mass-production/, Mar 3, 2017.

[2] “Custom Manufacturing vs. Mass Production”, http://apmmfg.com/index.php/custom-manufacturing-vs-mass-production/, Dec 8, 2016.

[3] Tushar Seth, “Advantages and Disadvantages of Large-Scale Production”, http://www.econom icsdiscussion.net/production/advantages-and-disadvantages-of-large-scale-production/ 1577, Sep 11, 2018.

[4] Li Guoping, Hou Yun, Wu Aizhi, 2017. Fourth Industrial Revolution: technological drivers, impacts and coping methods. Chinese Geographical Science, 27(4): 626–637. doi: 10.1007/s11769-017-0890-x

[5] “THE ADVANTAGES OF CUSTOM MANUFACTURING”, https://midlake.com/the-advantages-of-custom-manufacturing/, Jul 24, 2012.

[6] Alina Tugend, “Too Many Choices: A Problem That Can Paralyze”, https://www.nytimes.com/2010/ 02/27/your-money/27shortcuts.html, Feb 26, 2010.

[7] Aakanksha Gaur, “Lost-wax process”, https://www.britannica.com/technology/lost-wax-process, Aug 7, 2015.

[8] Spiegel, Rob. "3D Printing unalterably changes the design process: the design of products has been altered altogether through 3D printing. Parts that couldn't be produced at all before 3D printing came along are often superior to conventionally produced parts." Design News, Nov. 2016.

[9] Bulent Yusuf, “5 Reasons Why 3D Printing Industry Will Boom by 2020”, https://all3dp.com/5-reasons-why-3d-printing-industry-will-boom-by-2020/, Aug 25, 2015.